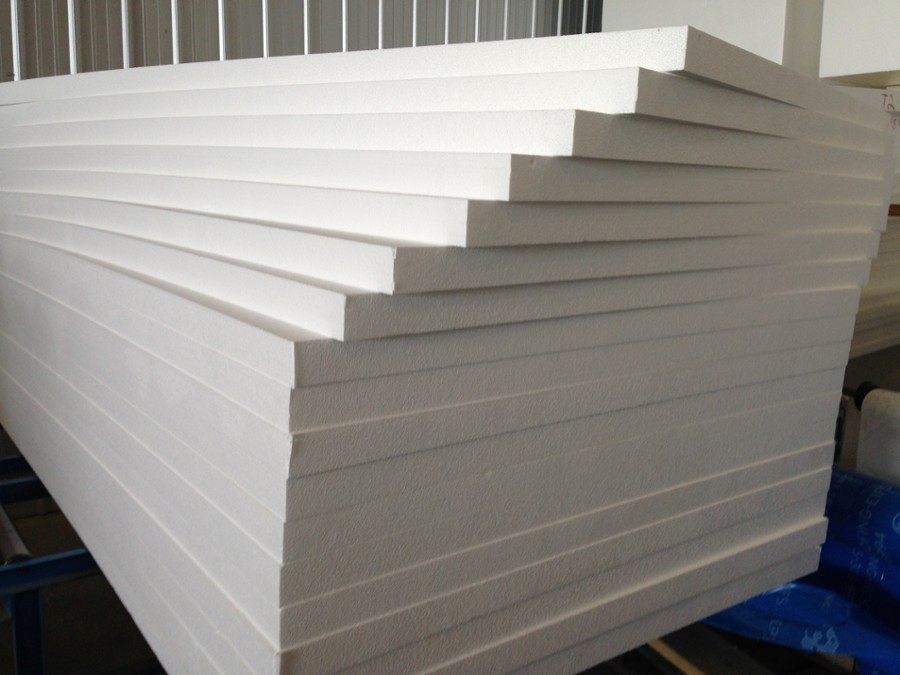

EPS foam is a type of plastic foam that is made from ethylene propylene Styrene (EPS) resin. EPS foam has many uses, including in products such as furniture and insulation.

When used in products, EPS foam is typically recycled by breaking it down into its parts. The various parts of the foam can then be processed separately to create new products or materials.

There are several ways to recycle EPS foam in Hawaii, depending on the type of product it was used in and the location where it was collected. Some methods involve using a thermal oxidizer to destroy the plastic, while others involve breaking down the pieces with a crusher or an extruder.

Image Source: Google

Overall, recycling EPS foam minimizes environmental impact by reducing the amount of waste produced and helping to reuse or recycle valuable materials.

EPS foam is a popular material for use in construction, insulation, and packaging. It is made of a mixture of hot air and gas that are blown into small bubbles. EPS foam provides good thermal insulation and can be recycled using several techniques to minimize environmental impact.

EPS foam can be recycled by compressing the foam and breaking it down into smaller pieces. The smaller pieces can then be heated and reformed into new EPS foam. This process can be done using a variety of machines, including an industrial compactor, hammermill, or crusher.

Another recycling method involves removing the plastic films that have been attached to the surface of the EPS foam. These films can be removed using a process called “ultrasonic cleaning”. Ultrasonic waves cause the films to break down and disintegrate. After the films are removed, the EPS foam can be compressed and reused as described above.

Overall, recycling EPS foam is an effective way to reduce environmental impact while providing products that meet customer needs.