Image Source: Google

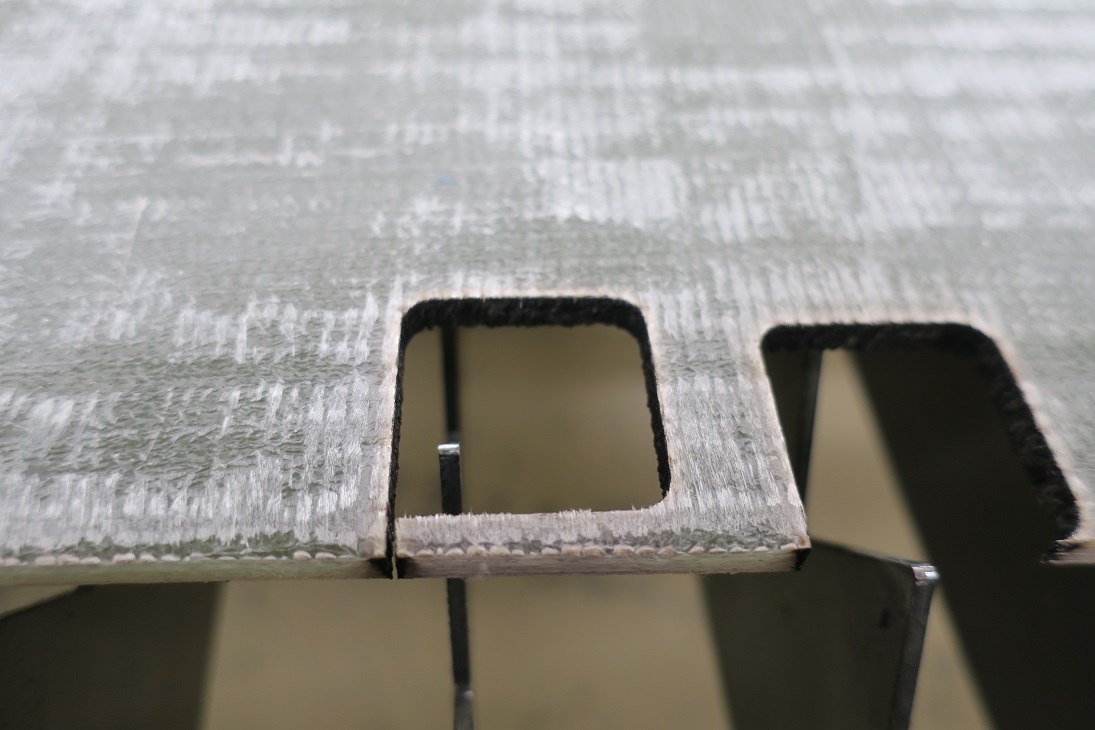

Polymers are versatile materials used in a wide range of industries, from automotive to medical devices. Laser cutting has become an essential process for shaping and manipulating polymers with precision and efficiency. Recent advancements in polymer laser cutting techniques have revolutionized the way these materials are processed, leading to improved quality, speed, and cost-effectiveness.

In this article, we will explore some of the cutting-edge solutions in polymer laser cutting techniques that are shaping the future of manufacturing. If you are looking for polymer laser cutting then, you may pop over to this site.

Advantages of Polymer Laser Cutting

Laser cutting offers several advantages over traditional cutting methods when it comes to processing polymers. Some of the key benefits include:

- Precision: Laser cutting provides high levels of precision, allowing for intricate designs and complex shapes to be cut with accuracy.

- Speed: The speed of laser cutting is significantly faster than traditional methods, leading to increased productivity and shorter lead times.

- Minimal waste: Laser cutting produces minimal waste compared to other cutting techniques, making it a more environmentally friendly option.

- No tool wear: Since laser cutting is a non-contact process, there is no tool wear, resulting in consistent quality and reduced maintenance costs.

Recent Advancements in Polymer Laser Cutting Techniques

1. Multi-Axis Laser Cutting Systems

Traditional laser cutting systems are limited to two axes of motion, which can be restrictive when cutting complex three-dimensional shapes. Recent advancements in polymer laser cutting technology have introduced multi-axis cutting systems that allow for greater flexibility and precision in cutting operations.

- Multi-axis laser cutting systems can move the laser head in multiple directions, enabling the cutting of intricate shapes and contours with ease.

- These systems are particularly beneficial for industries that require high levels of precision, such as the aerospace and medical sectors.

2. Ultrafast Pulsed Lasers

Ultrafast pulsed lasers have revolutionized polymer laser cutting by offering higher precision and reduced heat-affected zones. These lasers operate at extremely high speeds, delivering pulses in the femtosecond range, which allows for cleaner and more precise cuts.

- Ultrafast pulsed lasers are ideal for cutting thin and delicate polymer materials without causing thermal damage or deformation.

- These lasers are also capable of cutting reflective materials that are challenging for traditional continuous wave lasers.

3. Online Monitoring and Control Systems

To ensure the quality and consistency of laser cutting processes, online monitoring and control systems have been developed to provide real-time feedback and adjustments during cutting operations.

- Online monitoring systems use sensors to track key parameters such as laser power, cutting speed, and material thickness, allowing for immediate corrections if deviations are detected.

- This real-time monitoring helps optimize cutting parameters, improve efficiency, and reduce scrap rates.

Future Trends in Polymer Laser Cutting

As technology continues to advance, the future of polymer laser cutting is filled with exciting possibilities. Some emerging trends to look out for include:

1. Integration of AI and Machine Learning

The integration of artificial intelligence (AI) and machine learning algorithms into laser cutting systems is expected to revolutionize the way polymers are cut and processed.

- AI algorithms can analyze cutting data in real-time and make autonomous adjustments to optimize cutting parameters for improved efficiency and quality.

- Machine learning capabilities can also predict maintenance needs and prevent downtime by identifying potential issues before they occur.

2. Additive Manufacturing and Laser Cutting Hybrid Systems

Hybrid systems that combine additive manufacturing processes with laser cutting capabilities are on the rise, offering manufacturers greater flexibility and efficiency in producing complex polymer components.

- These systems can 3D print polymer parts and then use laser cutting to finish and refine the shapes with high precision.

- By integrating both processes into a single system, manufacturers can reduce production times and costs while increasing design possibilities.

3. Sustainability and Recycling Initiatives

With a growing focus on sustainability and environmental responsibility, the future of polymer laser cutting will likely see an increase in recycling initiatives and eco-friendly practices.

- New laser cutting techniques are being developed to process recycled polymer materials and reduce the industry's reliance on virgin plastics.

- By adopting sustainable practices and materials, manufacturers can not only reduce their environmental impact but also meet the growing demand for eco-friendly products.