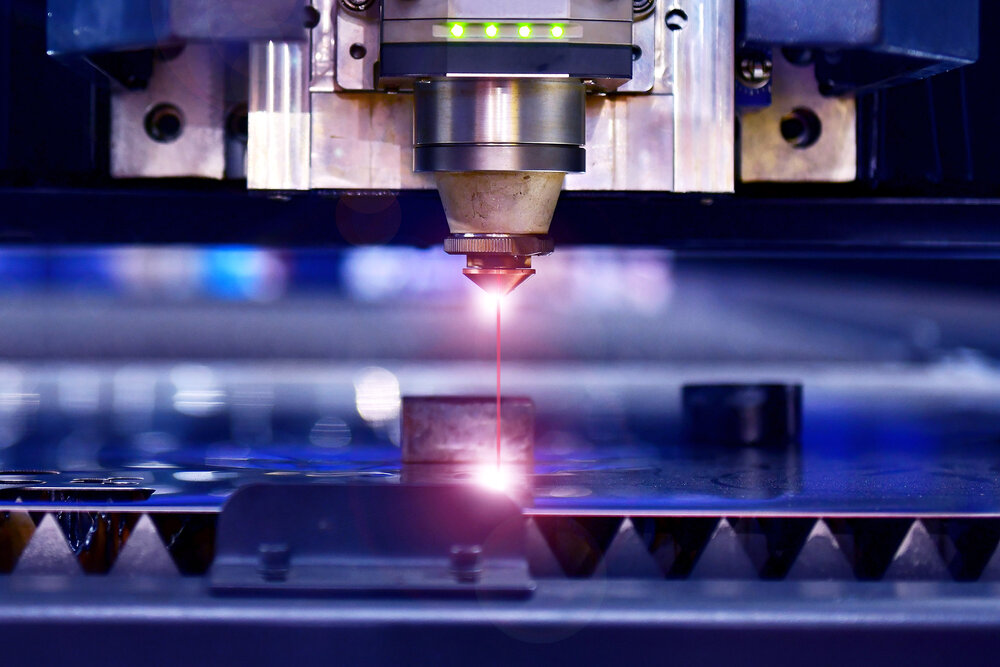

From heart rate management to neuromodulation to orthopedic implants and hearing, laser material processing systems play a key role in the creation of these life-enhancing devices.

Some of the most common applications of laser processing systems used in the manufacture of medical devices and the application database is growing rapidly. The basis of completely new products also lies in the availability of technology for laser machining systems. You may get the finest laser processing service from protolase.com/.

Image Source Google

The medical device industry has always valued laser systems. When they were first commercialized in the 1970s, lasers were adopted by industry. They have evolved along with the products they can make, enabling the design of new and improved medical products. For example, we are now in the phase of using ultra-short pulsed lasers, which provide negligible heat flux in medical device processing.

Laser technology can improve quality of life

Laser technology makes a difference in several important categories. For example, heart rate management (CRM) aims to improve the quality of life of people whose hearts often beat too slowly or fail to do so.

Several industrial laser processes are used to manufacture CRM devices, such as laser welding with a pulsed fiber laser to seal the pacemaker cartridges, disconnecting the electrode wires used for devices with Q-switching and short pulse lasers, and laser marking of UDI codes on devices with markers. fiber lasers.

Pacemakers have heat sensitive electronics in their assembly and this is one of the reasons laser systems were originally used in their production as clean heat transfer can be ignored or managed with well designed laser systems.